What is Detex ©?

The Detex © is the world's first ductless autonomous smoke detector and extractor. It automatically detects fire smoke, initiates its absorption at a rate of 192m3/h, filters the gases produced by the fire to 0.3 microns and purifies the ambient air:

- It sucks up and retains the soot present in the fumes to avoid poisoning,

- It filters carbon dioxide and makes the atmosphere more breathable,

- It reduces carbon monoxide by 6%,

- It lowers the room temperature by 30°C and allows better visibility,

- It works for 30 minutes in total autonomy after a power cut,

- It is equipped with a smoke alarm integrated in standard NF-EN 14604

A true technological innovation, this solution meets the smoke extraction objectives defined by the regulations:

- Maintain practicable evacuation routes.

- Also help to limit the spread of the fire and facilitate the intervention of the emergency services.

The Detex is guaranteed for 10 years (excluding battery).

A certified and award-winning technological innovation, patented worldwide

Detex © is a worldwide patented French technological innovation, the first model of which won the Preventica Safety/Safety Innovation Award (2015). It was developed by Experts, in particular with the collaboration of CREPIM, DT Filtre and Fire men experts.

All Detex © components are certified to French, European, American and/or Canadian standards, and guaranteed for 10 years (excluding battery).

All certifications have been obtained from leading organizations.

All Detex © installations have been validated by reference control offices.

It has been designed to be FUNCTIONAL, AESTHETIC and ECONOMIC.

It is an ALTERNATIVE and complementary solution to conventional smoke extraction solutions.

Presentation of the Detex ©.

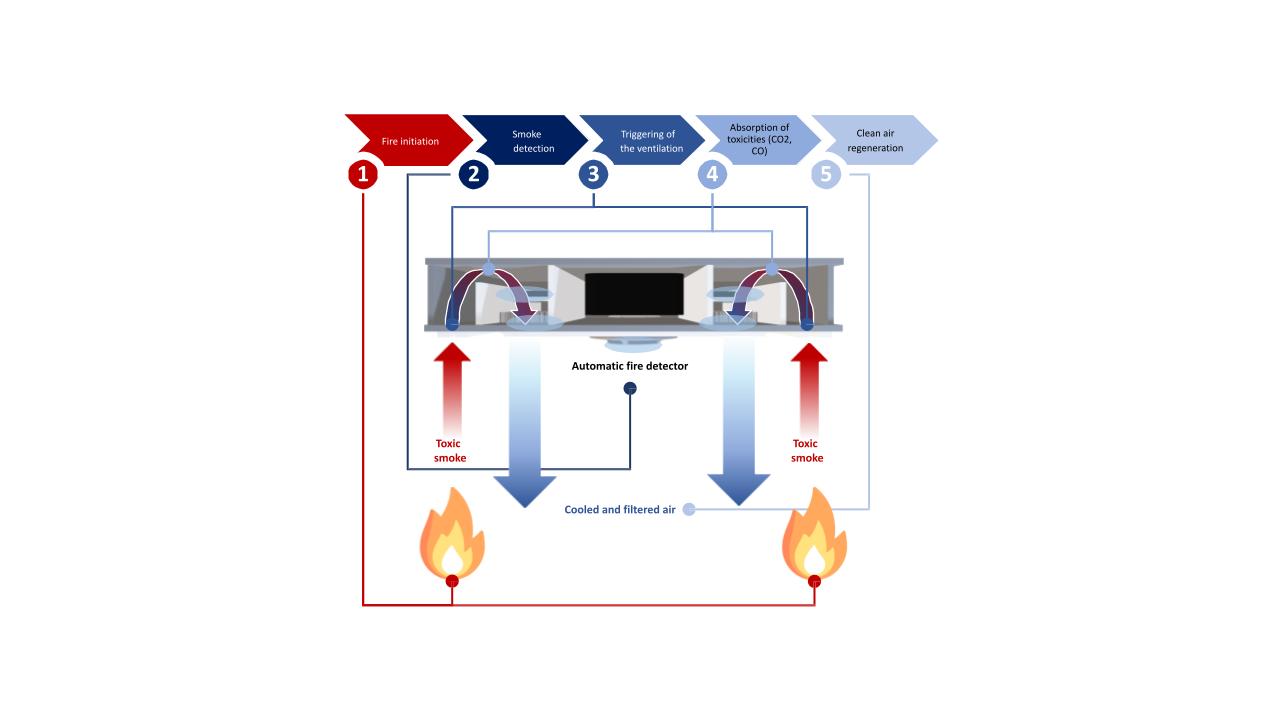

How the Detex © works?

At automatic detection, the smoke is processed early through Detex © located on the ceiling. The treatment of fumes is favored by the air intakes, the large circulations, a good height under ceiling and the absence of a dead end.

Adequately distributed and sufficient number of air intakes increase the efficiency of flue gas treatment and reduce the concentration of toxic gases as well as the temperature. Note that the simulation must show that the thickness of the smoke is never greater than 1.80 m in height.

The installation of Detex © leads to good results on the basis of compliance with the instructions for use and safety communicated.

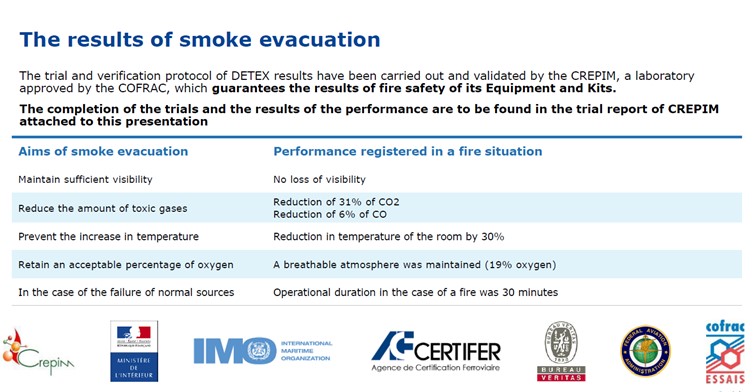

Results of smoke evacuation

A true technological innovation, this solution meets the objectives of smoke evacuation defined by current regulations:

▪ Maintaining evacuation paths practicable.

▪ Also helping to limit fire spreading and to facilitate the intervention of rescue teams

Sizing principles for the smoke extraction solution

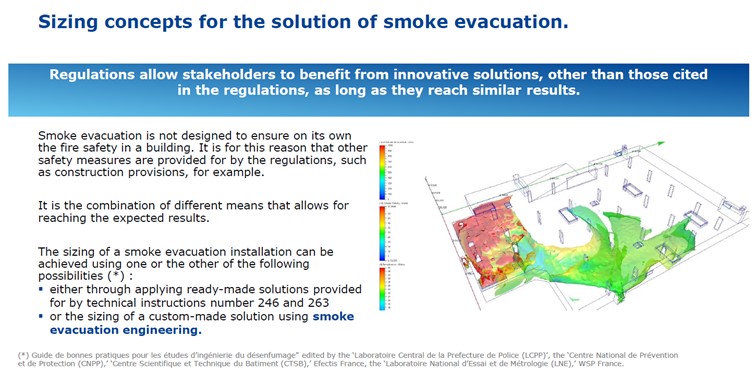

The ISO 16733 standard describes the methodology for selecting fire and fire scenarios as well as the dimensioning to be used for fire safety engineering and observation of the achievement of results.

In all cases, the project owner is solely responsible for deciding whether to use smoke extraction engineering as authorized by chapter 8 of IT 246 for the sizing of smoke extraction solutions other than those alternatives to the solutions described in IT 246.

Depending on the characteristics of the areas to be protected, we carry out smoke extraction engineering to determine the quantitative requirements of DETEX as authorized by the chapter of IT 246.

The reliability of the smoke extraction system lies in the combination of several DETEX

Sizing the solution: smoke extraction engineering (CFD)

Introduced in France by the decree of March 22, 2004, the CFD (Computational Fluid Dynamics) for smoke extraction allows for the use of advanced scientific methods to assess the level of safety of a project, where prescrptive regulations are not optimal.

The CFD is applicable in the case of works and infrastructures, such as high-rise buildings, plants and factories, residential buildings, as well as well as road, railway and maritime transports. It is essential in the event of constraints such as high calorific potential, specific furbishing, impossibility of quartering areas, renovation or securing of existing buildings, and other unusual or non-standard occurrences.

The engineering studies are based on assumptions and safety objectives closely linked to the performance criteria of the solution and system under review. Such solutions depend on the adaptation of means designed to answer the involved risks, through the simulation of different realistic scenarios validated by an authorized fire security design office.

Fire and smoke extraction simulations allow for accurate prediction of smoke and heat development and spreading inside a building. Thus, the CFD simulation provides a 3D observation of the complex smoke flow process inside a building.

The objective is to assess and understand the air flow profile and the spreading of smoke over time in all the spaces concerned during a fire. The study also highlights the identification of dead air pockets, provides an assessment of average air age, fan throw and air velocity in the building. By using advanced computer modeling techniques, the CFD allows fire security engineers to simulate the building with several detailed diagrams of smoke extraction systems. Virtual building modeling details smoke and fire behavior, allowing airflow patterns to be examined with detailed maps over time ; this is intended to show how the smoke is likely to spread, and makes it possible to establish the best smoke ventilation design system for the building. The CFD simulation also helps to determine the thermal rise throughout the building by providing a detailed analysis of the exchanges involving fluid flow and heat transfer, by taking into account various fire scenarios.

Optimization of fire security and smoke extraction

When one considers complex buildings, it happens that existing guidelines and regulations are sometimes too general to assess accurately all the interactions between a fire and the development of flue gases. Thus, in France Smoke Extraction Engineering and IT246 Chapter 8 allow for an innovative technical solution to be fully validated by a relevant control office, provided that the solution is functional.

When we design a smoke extraction concept using the DETEX © solution, we therefore rely on calculation methods where the interaction of the following criteria are taken into account:

- Location of the fire and ventilation of the room;

- Fire smoke and blown air;

- Fire smoke and exhaust air;

- Ambient and thermal pressure;

- Impact of an unfavorable wind;

- Starting time of the DETEX ©.

The digital simulation provides an accurate calculation of smoke, temperature and pressure curve over time:

- The height of the smoke layer (clearance);

- Temperature distribution in the different areas;

- Flue gas concentration and distribution;

- Temporal and spatial evolution and spreading of smoke gases;

- Visibility through.

The CFD aims to ensure the proper evacuation of the occupants of a structure in the event of a fire. It provides an alternative response by making it possible to offer taylor-made solutions, such as the DETEX © solution, while guaranteeing a full compliance with the objectives set by the regulations.

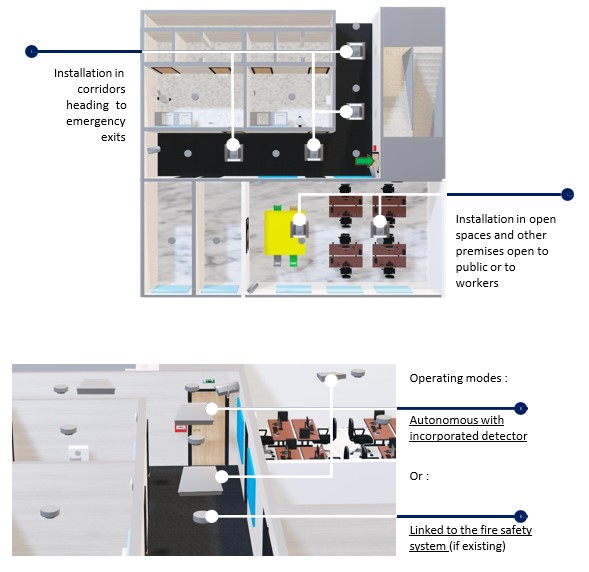

- Installation in open spaces and other premises open to the public and/or workers

- Installation in corridors leading to emergency exits

Operating modes:

- Autonomous with their own detector

- Liked to fire detectors (if existing)

Principles and methodology for the implementation of Detex ©

1 . Positioning of Detex © according to the nature of the premises and regulations, according to the following criteria:

In premises of more than 300 m² (100 m² for blind premises) upstairs or on the ground floor

- A Detex © for 50 m² if the calorific potential is normal;

- A Detex © for 30 m² if the calorific potential is high.

In all common horizontal circulations:

- A Detex ©every 7 linear meters

- A Detex © every 5 linear meters in the event of non-straignt traffic

- c) In all stairwells;

- d) In all SAS.

- Verification of the installation by carrying out smoke extraction engineering (CFD) and a simulation in 3D view

Functioning principles

With automatic detection, the smoke is treated early via the Detex © located on the ceiling. The treatment of fumes is favored by the air intakes, the wide circulations, a good height under the ceiling and the absence of dead ends.

Air intakes judiciously distributed and in sufficient number increase the efficiency of the flue gas treatment and reduce the concentration of toxic gases as well as the temperature. HAS note that the simulation must show that the thickness of the smoke is never greater than 1.80 m height.

The installation of Detex © leads to good results on the basis of compliance with the instructions for use and safety communicated.